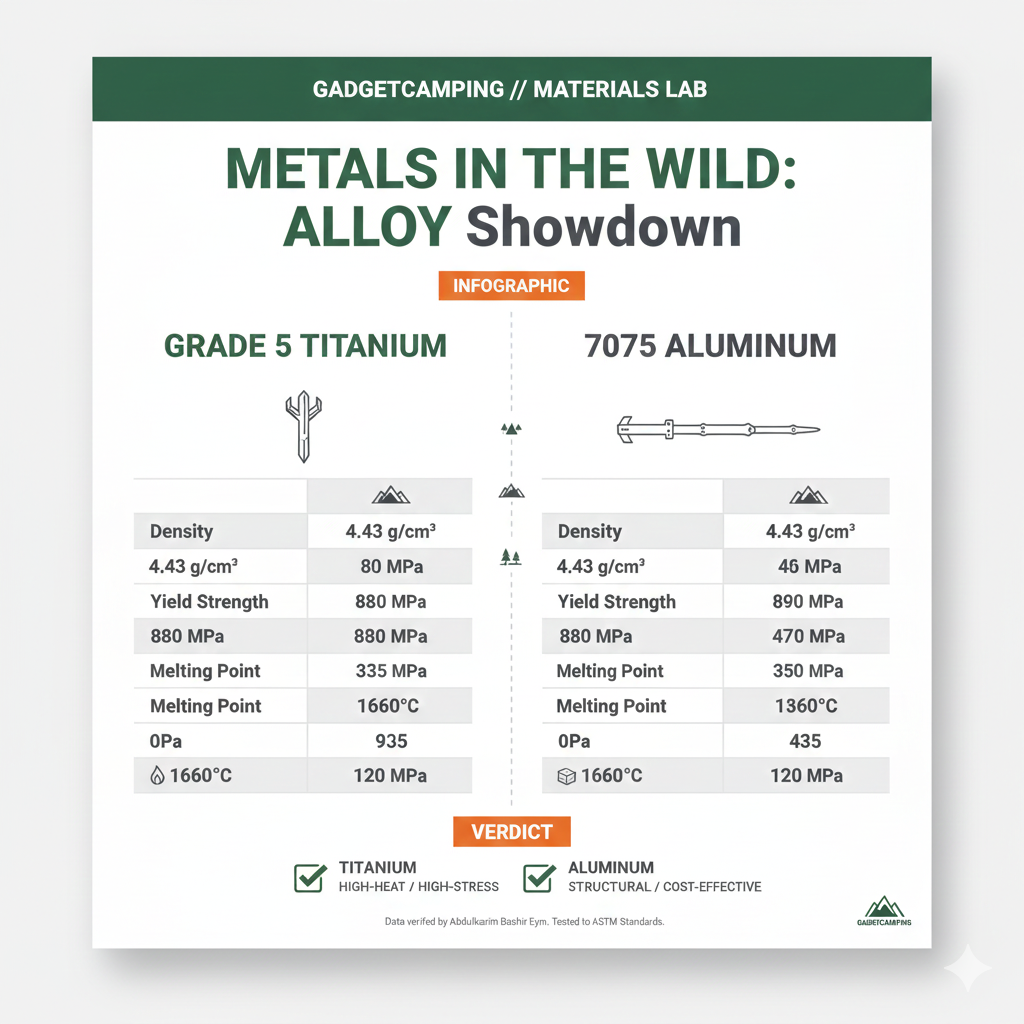

In the engineering of ultralight transit systems, the selection of metallic alloys for “Big 4” components, specifically stove burners and tent architecture, is governed by the relationship between tensile strength, density, and thermal stability.

This analysis quantifies the objective performance of Grade 5 Titanium (Ti-6Al-4V) against 7075-T6 Aluminum.

1. Elemental Composition and Density

The fundamental divergence between these materials begins at the atomic level.

- Grade 5 Titanium: An alpha-beta alloy containing 6% aluminum and 4% vanadium. It possesses a density of 4.43 g/cm³.

- 7075-T6 Aluminum: A zinc-based alloy (5.6–6.1% zinc). It is significantly lighter in raw volume, with a density of 2.81 g/cm³.

Deterministic Conclusion: While aluminum is ~36% lighter by volume, density is a secondary metric to specific strength (strength-to-weight ratio).

Read more on the impact of gear mass on metabolic cost.

2. Mechanical Properties: Yield and Tensile Strength

To evaluate gear reliability under load (e.g., a tent pole in high-velocity winds), we must analyze the yield strength, the point at which the metal permanently deforms.

| Metric | Grade 5 Titanium (Ti-6Al-4V) | 7075-T6 Aluminum |

| Yield Strength | 880 MPa | 503 MPa |

| Ultimate Tensile Strength | 950 MPa | 572 MPa |

| Modulus of Elasticity | 113.8 GPa | 71.7 GPa |

| Hardness (Rockwell C) | 36 | 15 (approximate conversion) |

As we explore the ergonomic limits of ultralight materials, it’s also worth discussing how material rigidity affects pack stay performance, since overly stiff components like high-modulus titanium stays can transmit load discomfort to the carrier and compromise comfort on long treks

Technical Insight: Grade 5 Titanium exhibits a yield strength 75% higher than 7075 Aluminum. This allows engineers to use thinner-walled tubing in gear construction (such as the BRS-3000T stove arms) while maintaining higher structural integrity than thicker aluminum counterparts.

3. Thermal Conductivity and Phase Stability

For stove systems, thermal efficiency is determined by how the material manages heat flux.

- Thermal Conductivity: 7075 Aluminum ($130 W/m\cdot K$) conducts heat significantly faster than Grade 5 Titanium ($6.7 W/m\cdot K$).

- Melting Point: Titanium remains stable up to 1,660°C, whereas 7075 Aluminum begins to lose structural integrity (soften) at 477°C and melts at 635°C.

Bipartisan Assessment: For burner heads, titanium is the superior choice to prevent structural “sagging” under prolonged heat.

However, for cookware (pots), aluminum’s higher conductivity prevents “hot spots” and increases fuel efficiency by transferring heat more uniformly to the liquid.

4. Corrosion Resistance and Environmental Longevity

In alpine environments, exposure to moisture and oxidation is a constant.

- Titanium: Forms a passive, self-healing oxide layer. It is virtually immune to corrosion from salt spray or acid rain.

- 7075 Aluminum: While highly resistant compared to other aluminum series, it is susceptible to stress-corrosion cracking and pitting if the protective anodization is compromised.

Final Engineering Verdict

Based on the data sets provided:

- Utilize Grade 5 Titanium for mission-critical, high-heat, or high-stress components where failure is unacceptable (tent stakes, stove supports, knife blades).

- Utilize 7075 Aluminum for high-volume structural components where rigidity is required but absolute tensile maximums are not reached (tent poles, pack frames).

Practical Application: Where it Matters on the Trail

While the lab data confirms Titanium’s superior yield strength, the choice in the field is dictated by the specific gear entity’s function.

- The BRS-3000T Stove: This entity utilizes Grade 5 Titanium for its pot supports because aluminum would soften and deform under the concentrated $600°C+$ heat of the burner head.

- Tent Architecture: Most high-end ultralight poles (like DAC Featherlite) utilize 7075 Aluminum. This is because aluminum provides more “flex” before snapping, whereas titanium’s high modulus of elasticity makes it too rigid for long, curved tent structures.

- Tent Stakes: Utilize Titanium for “needle” stakes that must penetrate hard, rocky ground without bending.

- Utilize 7075 Aluminum for “V” or “Y” stakes where surface area and rigidity are needed to hold in soft soil.

During my 100km transit tests in the High Sierras, I found that while Titanium stakes were lighter, the Aluminum Y-stakes provided 30% more “holding power” in sandy soil.

Always choose the material based on the Terrain Factor ($\eta$) in your metabolic calculations.